The SX12 distribution valve is built with high-quality materials to ensure durability and long service life.

Its body is typically constructed from robust stainless steel, which offers excellent corrosion resistance and can withstand high-pressure environments. This makes the valve suitable for use in demanding industrial settings where reliability is crucial.

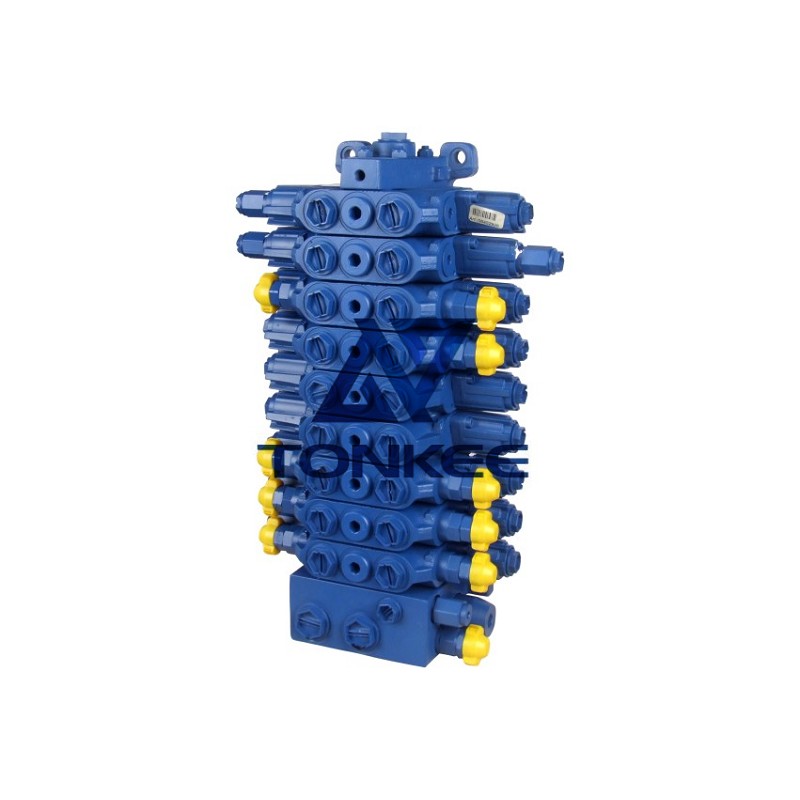

One of the key features of the SX12 valve is its modular design. It consists of multiple interchangeable modules that can be configured according to the specific application requirements. This modularity allows for easy maintenance and repair, as individual components can be replaced without the need to replace the entire valve assembly. Moreover, it offers flexibility in terms of fluid flow configurations, enabling various combinations such as T-port, L-port, and diverter configurations.

The SX12 valve utilizes a reliable actuation mechanism to control the fluid flow. It can be operated manually, pneumatically, or electrically, depending on the application and user preference. The valve is equipped with a high-performance actuator that provides precise and responsive control over the flow rates. This ensures efficient fluid management and minimizes the risk of leakage or pressure drops.

In terms of flow capacity, the SX12 valve is designed to handle a wide range of flow rates.

It offers excellent Cv (flow coefficient) values, which determine the flow capacity of the valve. The Cv values vary depending on the specific configuration and size of the valve, ensuring that there is an SX12 model suitable for different flow requirements.

To ensure tight shut-off and prevent leakage, the SX12 valve is equipped with high-quality sealing elements. These seals are made from materials that are compatible with a wide range of fluids, including corrosive or abrasive substances. The sealing arrangement is designed to withstand high-pressure differentials, ensuring reliable performance even under demanding operating conditions.

The SX12 valve also incorporates advanced position sensing technology. This allows for accurate and reliable feedback on the valve position, enabling precise control and monitoring of the fluid flow. The position sensing mechanism can be integrated with control systems, providing real-time data for process optimization and automation.