The CM-SF-40A, VCM-SF-40B, VCM-SF-40C, and VCM-SF-40D displacement vane pumps are part of the SF-40 series, which is known for its advanced features and versatility.

These pumps have a common displacement of 40 cubic centimeters per revolution, making them suitable for a wide range of hydraulic systems with moderate flow requirements.

One of the key advantages of these vane pumps is their ability to provide consistent fluid flow and pressure. The vane mechanism inside the pump housing ensures smooth and efficient operation, minimizing pressure pulsations and ensuring a steady flow of fluid. This feature is particularly crucial in applications where precise control over fluid flow is necessary.

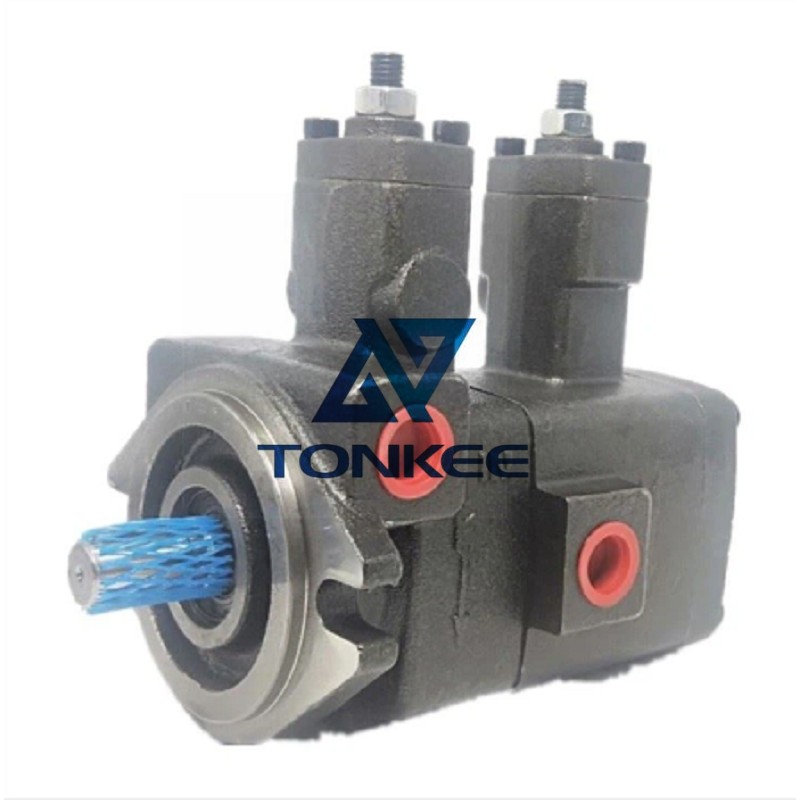

The design of these displacement vane pumps also focuses on durability and long-term performance. The pump bodies are made from high-quality materials, such as cast iron or aluminum alloy, which offer excellent strength and resistance to wear and corrosion. This robust construction ensures that the pumps can withstand demanding working conditions and provide reliable operation over an extended service life.

Furthermore, these pumps are designed for easy installation and maintenance. They have a compact and lightweight design, allowing for flexible mounting options in various system configurations. Additionally, the pumps are equipped with replaceable vane cartridges, which simplifies maintenance procedures and reduces downtime. This feature enables quick and cost-effective repairs, ensuring minimal disruption to the overall hydraulic system.

The CM-SF-40A, VCM-SF-40B, VCM-SF-40C, and VCM-SF-40D displacement vane pumps offer versatility in terms of fluid compatibility.

They are suitable for use with a wide range of hydraulic fluids, including mineral oils, synthetic fluids, and biodegradable fluids. This versatility makes them suitable for various industries, such as manufacturing, construction, agriculture, and more.

These displacement vane pumps also incorporate several safety features to protect both the pump and the hydraulic system. They are equipped with built-in pressure relief valves, which prevent excessive pressure buildup and safeguard against potential damage. Additionally, the pumps have efficient filtration systems to ensure clean fluid intake, reducing the risk of contaminants that could impair pump performance.